These sockets were the control interface for some rackable 3.3kV motor contactors, they were 30 years old and they had a problem. When ever the plug was removed, the socket would come with it as well – leaving us with the real risk of exposed live parts, or shorting control circuits. It turned out that these sockets had been held in by some spring clips, that had sprung over their lifetime.

The plugs and sockets were still readily available, but shutting down the entire plant, and replacing all 54 sockets was quite the task. So I came up with another idea – what if we could make a piece of steel that surrounded the sockets, but still had clearance enough to let the plugs connect.

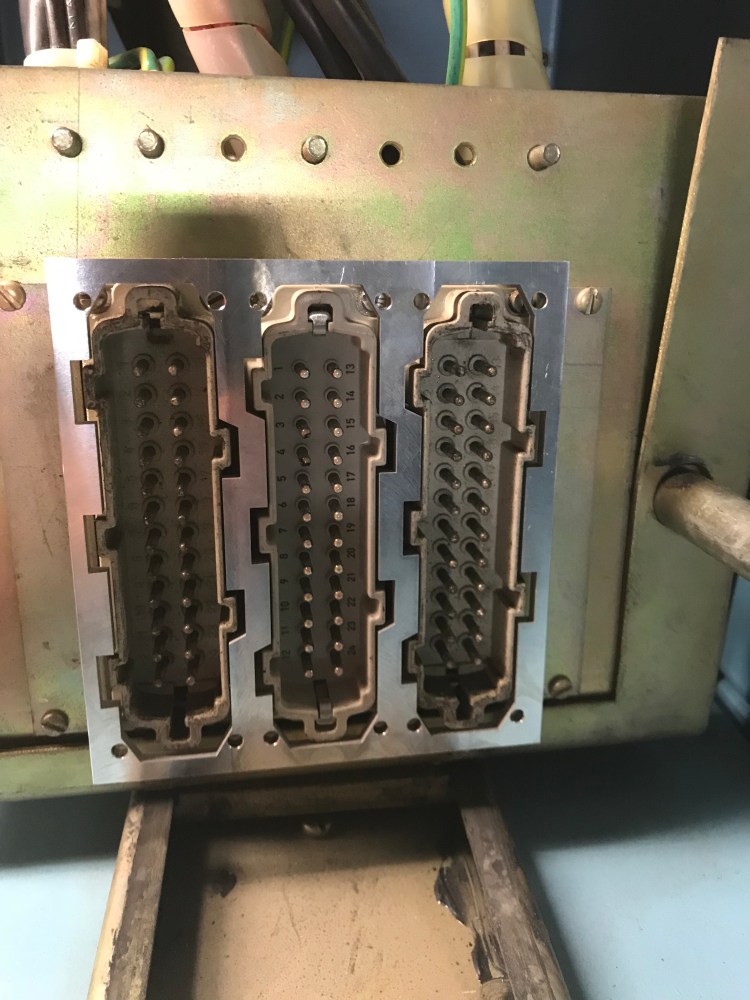

After some careful measuring, and some time drawing up a CAD file to send off to the local CNC fabrication shop here is the 1st prototype against the plug section showing the clearances.

It worked, and a couple of days later we had received the remainder of the order. We had gone from days worth of weekend work, with recommissioning and inspection to simply one day for someone to walk around and install. Below is prototype bracket installed on the socket side. Although not strictly electrical, it certainly remains one of my favourite jobs.